Industrial Equipment Installation

Magnetite FM installs a multitude of equipment designed to protect and enhance a facility such as barriers, Mats, Packing Stations, Heavy Cables, Shelving and so much more.

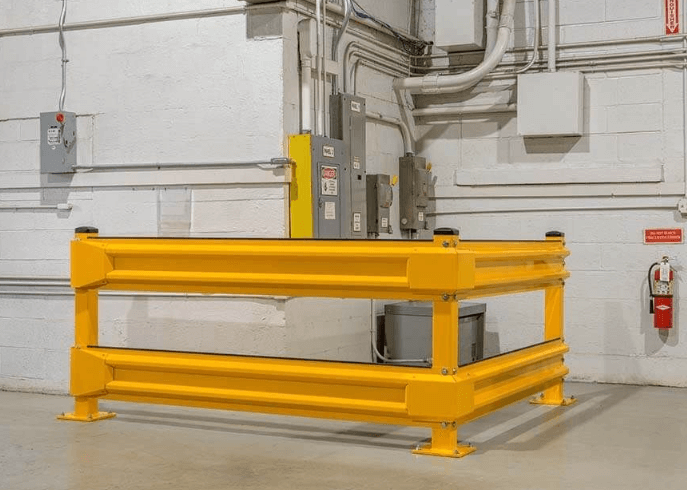

Barriers

Warehouse barriers play a crucial role in ensuring the safety and efficiency of warehouse operations. These barriers are physical structures strategically placed within the warehouse environment to prevent accidents, protect assets, and guide the flow of traffic. One common type of barrier is the guardrail, which is often installed along walkways, loading docks, and other high-traffic areas. Guardrails act as a protective barrier, preventing forklifts and other equipment from accidentally colliding with pedestrians or causing damage to inventory.

In addition to guardrails, warehouses may utilize bollards, safety nets, and other types of barriers to create designated zones, control access, and mitigate the risk of workplace accidents. The careful planning and implementation of these barriers contribute to a safer working environment, reducing the likelihood of collisions, injuries, and property damage. By incorporating effective warehouse barriers, businesses can optimize their operational processes while prioritizing the well-being of their personnel and safeguarding valuable assets.

Packing Stations

The installation of a packing station is a pivotal aspect of warehouse logistics and order fulfillment processes. A packing station is a designated area within a warehouse where products are prepared for shipment to customers. During the installation process, careful consideration is given to the layout, efficiency, and accessibility of the packing station. Common elements include packing tables, packaging materials, labeling systems, and often integrated technology such as barcode scanners and weighing scales. The goal is to create an organized and streamlined environment that facilitates the accurate and timely packing of orders, reducing errors and enhancing overall operational efficiency. The strategic placement of packing stations within a warehouse contributes significantly to the fulfillment speed, order accuracy, and overall customer satisfaction in the supply chain.

We are dedicated to keeping your facility looking its best and operating in peak condition.

Stop Plates

Stop plates are essential components used in various mechanical and industrial applications to limit the movement or prevent the overtravel of a sliding or rotating element. These plates, often made of durable materials like steel or aluminum, are strategically positioned along a track or surface where the moving part is intended to come to a halt. The design of stop plates is crucial in ensuring precision and reliability, and they are commonly used in conveyor systems, manufacturing equipment, and automated machinery. By incorporating stop plates, engineers and manufacturers can enhance the safety and control of automated processes, preventing damage to equipment and ensuring that operations cease when and where intended, ultimately contributing to the overall efficiency and safety of industrial systems.

Typically constructed from durable materials like steel or alloys, stop plates are engineered to withstand the forces associated with abrupt deceleration, making them reliable components for maintaining operational safety and preventing damage to machinery. Their versatility and precision make stop plates integral for enhancing the efficiency and safety of diverse industrial applications.

Warehouse Shelving

Warehouse shelving is a fundamental component of efficient storage and organization within distribution facilities. These shelves are designed to maximize vertical space, providing a systematic and accessible way to store goods and materials. Warehouse shelving comes in various forms, including pallet racks, boltless shelving, and mobile shelving systems, each tailored to specific storage needs. Pallet racks, for example, allow for the stacking of palletized goods, optimizing floor space. Boltless shelving provides flexibility and ease of assembly, accommodating a range of products. Mobile shelving systems offer high-density storage solutions with the ability to compact and expand as needed. The choice of warehouse shelving is crucial for maintaining order, facilitating inventory management, and improving overall operational efficiency in the dynamic environment of a warehouse.